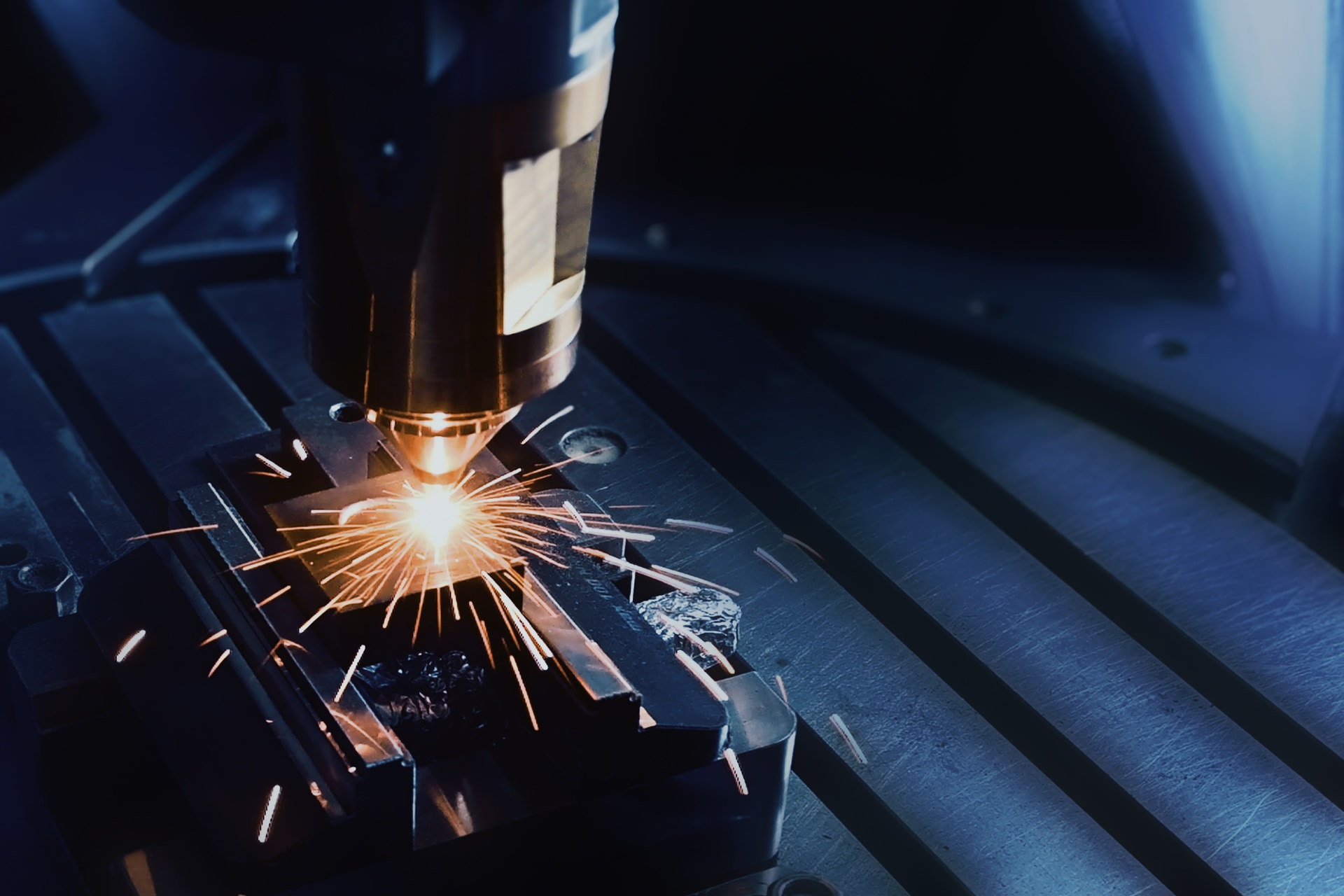

DED Services

Your competent partner for Directed Energy Deposition: Laser powder based cladding – from simple coating to complex 3D structure, including finishing!

We support you from the initial classification phase, e.g. whether and where the technology can be technically meaningful and commercially successful for your specific context, through the planning of a processing strategy and embedding in your application, to production technology qualification and implementation on our or your systems!

In addition to our own capacities, we have direct access to a highly specialized network of suppliers of upstream and downstream process steps, as well as partners with whom we can solve and advise on special requirements – feel free to contact us with your individual challenges!

Services

DED Services

- Laser-Powder-DED with our own system: LASERTEC 65 DED hybrid – ADDITIVE MANUFACTURING Machines by DMG MORI – DMG MORI UK

- Pre-, intermediate-, finsh processing in one system and fixture (esp. milling, turning, drilling)

- Heat treatment (pre-, post-treatment in-situ by Laser and/or furnace based)

- Metrological recording and documentation of process variables, component dimensions (e.g. compliance with tolerances using contactless and optical measurement technology)

- Standard-compliant qualification

DED Consulting

- Consulting in all phases of project life: from fundamental considerations to feasibility tests, qualification, start-up and production issues

- Option to supporting the above activities by transferring customer technology to our system technology and re-transferring to customer systems

- Calling in third-party partners from our large technology and industry network as required

- Metallographic analysis, findings and derivation of recommendations for action

Machining

- Milling, turning, drilling, thread cutting etc., up to 5-axis, CNC-controlled and conventional, see Meissner Mechanik GmbH Maschinen- und Apparatebau (mm-he.de)

- Further processing steps, e.g. laser cutting, vibratory/flat cylindrical grinding, glass bead blasting

- Further treatment, e.g. by shot peening, deep/flat rolling

Powder based laser cladding is referred to in the latest standards as LP-DED, which stands for Laser Powder Directed Energy Deposition. The process differs from other DED processes, such as laser-based wire processes, powder- or wire-based arc processes and powder bed 3D printing, in that it has a number of unique features and advantages.